|

Magging an Avet JX

Moving to California

from the Great Lakes region I found myself researching extensively for my

first ocean reel. I wanted quality and value. I also wanted a general all

around reel that I could make do for a variety of conditions and targets. I

eventually purchased a Avet JX from the Charkster that I chose as a reel to

cover 95% of any situation I might encounter on any 2 day trip out of

southern California.. I can stuff 400 + yds of 30lb. Spectra with

appropriate fluorocarbon leader on this reel. Its bolted to a 7 ft.

15-40 LB class graphite rod, I could not be happier.

Well, yes I could be

happier. This wonder reel has excellent free spool. While this feature is

desirable for fly lining and indicates an exceptionally well engineered

reel, this amazing feature requires a highly educated thumb when casting

for maximum distance. Casting with 75% effort presents little problem for

skilled anglers . Its when you really crank in the power to get that maximum

distance that problems arise. Lets redefine “problems” as “backlash

extrodinare”. Yes, it can be minimized but the thumb control required

negates a lot of the distance potential for the extra power exerted.

I needed a solution to

this annoyance. After an extensive net search of long distance casting I

came across some East Coast sites where shore fishermen were MAGGING their

reels for max distance when surf casting . I also learned that Magging a

reel is not rocket science and is easy to do. Magging is nothing new. It has

been around for some time and is used today by various manufactures in

selected models.

Why magging works is a

result of the application of Lenz’s Law. Basically, when a rotating metallic

object (your reel spool) is within a magnetic field an opposing field is

induced into the rotating metal which counteracts the field of the

stationary magnet. Consequently resistance is induced into the spool

slowing it down. The strength of this resistance is proportional to the

rotational speed of the spool and the strength of the magnet. Thus the

maximum amount of resistance is generated at maximum spool speed and is

viturelally non-existant at slow rotational speeds. Backlashes are

generated when the spool speed exceeds the speed required to feed line out

to the object that has been cast. Magging stops the backlash because it

applies spool resistance when it is needed most, at maximum spool speed.

The following are

detailed instructions on magging a reel. I will outline what I did to Mag

the Avet JX but the basic principal can be applied to any reel that has a

metallic spool.. Graphite or composite spools cannot be magged.

You will first need a

source for magnets. Not your ordinary magnets but the strongest available

magnets that you can buy. Neodymium Iron Boron Rare Earth Magnets are the

only type to use. Do not substitute. These Rare Earth Magnets are 50

times stronger than standard magnets and their effect can be increased by a

factor of 2 to 4 with proper installation. They can be purchased on line

at: www.leevalley.com, or phone # 800 871 8158. On the web site go to

Hardware then go to Magnets. To properly educate yourself read

the “About Rare Earth Magnets” page. It is a must read.

Now, order the

following: Minimum of 3 each.

#99K31.01 Magnet ¼” OD

- 1/10” Thick

#99K32.03 Magnet 3/8”

OD - 1/10” Thick

#99K32.51 Cup for ¼”

Magnet

#99K32.52 Cup for 3/8”

Magnet

#99K32.61 Washer for ¼”

Magnet

#99K32.62 Washer for

3/8” Magnet

As you can see on the

web site the material is top notch and inexpensive.

This order will give

you ample supplies to mag a couple of reels and allows for a blunder or

two. You will need some standard air dry hobby glue, even Elmers will work.

You will also need a small amount of 2 part epoxy for final attachment of

the magnets to the inside of the reel. I like JB Weld, its bullet proof but

any Epoxy will do. And some type of degreaser to clean a spot inside the

reel so the epoxy will stick to the reel. I use isopropyl alcohol. You

might also need access to a small bench grinder to shape the magnet and or

magnet base if necessary. You can use a file if you cannot get access to a

grinder. And finally some light grease to coat the magnet and its base for

salt water corrosion protection. I use Silicone grease but almost any type

will suffice. You can always take a Q-Tip and spread some existing grease in

your reel over the magnet assembly.

There are three ways to

mount the magnets. By itself, on a steel washer and inside the correct size

steel cup. By itself is one strength value, on a steel washer produces 2X

the rated strength of the magnet and inside a steel cup produces 4X the

rated strength of the magnet used. Explanation of these values are on the

Lee Valley Site.

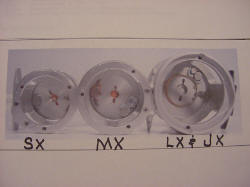

Below shows the

Magnets, Flat Washers and Cup Holder for the

¼” & 3/8” sizes.

Remove the 2 screws on

the handle side of the JX and remove the entire side plate and spool

assembly. Real simple. Now the magnet assemble chosen will be attached to

the inside of the end housing opposite the handle. Mount the magnet assemble

as far out from the center as possible. My JX has a clicker assemble so I

mounted the magnet assembly next to the OD of the clicker brass ring. What

magnet you use and what steel backing you use depends on trial and error.

You will have to experiment with this. Take a look at the pics supplied to

get the idea. You install just a magnet, a washer and a magnet or a cup and

magnet, just guess to start.

1.

With the

dismantled reel in the vertical position place the chosen magnet,

washer/magnet or cup/magnet combination on the inside back plate as far to

the outside as possible then carefully re-assemble the reel, do not screw

down yet, now rotate the spool to check for interference between the

installed magnet assemble and the rotating spool. Interference will show up

as the inability to re-assemble the reel because the magnet assemble is too

high or when you rotate the spool it will move the magnet assembly from the

original position that you placed it. Do what ever is necessary to create

clearance between the magnet and spool. They must not touch. Some

suggestions would be to grind down the thickness or the edge of the steel

washer or the top edge of the magnet may need clearance. All adjustments

must be made to the steel washer or magnet, do not grind on your reel

housing or spool. If modification of the magnet is required, and you are

using a grinder, be sure to keep the magnet cool by submerging in water

every few seconds of grinding as temperatures above 400 deg.F will destroy

the strength of the magnet. Now insert the 2 screws and tighten down and

re-check for clearance and adjust as necessary.

2.

De-grease the

end plate and magnet assembly with the alcohol and attach the steel washer

or cup with the air dry glue. Let set overnight. The air dry glue is used so

it can be removed easily for the next trial magnet set up. Now just set the

magnet you have chosen on top of the steel washer or in the cup. Don’t worry

it will stay put. Now re-assemble the reel, do not bolt down, just hand

assemble and carefully check for spool clearance again between the magnet

and the spool.. If it does not clear adjust some thing accordingly. All

should be as it was before.

3.

Now take a

dummy plug or iron, (1-3 oz) remove the hooks, go to the local park and

start casting. Lightly at first, keep increasing power until either you have

no more power or backlashes start being generated. If you are casting with

full power and you are getting no backlash at all you have too much control.

You need to reduce the magnetic force until you just start to get a little

loose line, not a backlash, once in a few cast. This will be just about

right. You can however adjust to your own personal preference.

4.

You reduce

magnetic force by increasing the distance between the magnet and the spool,

going from a cup to a flat washer or no washer, using a smaller magnet or

fewer magnets or any combination of the above. If you need to increase the

magnetic force decrease the distance between the magnet and the spool, go

from a flat washer to a cup installation, install a bigger magnet or more

magnets or any combination of the above . ( if you install multiple

magnets be sure the polarities are in the same direction)

5.

When you have

developed a combination you like remove the set up from the reel, scrape

off all the air dry glue, clean with alcohol and re-attach with Two part

Epoxy. Always re-check for clearance. Finally, coat the entire modification

with grease for corrosion protection. Below Pic shows the completed Magging.

For the Avet JX I

ended up using a 3/8”magnet inside a 3/8 steel cup with about .010” ground

off the bottom of the magnet cup and the outside top edge of the cup ground

down to clear the outer edge of the spool and the inside of the cup ground

to move the entire assembly closer to the center so there would be room for

the spool lip.

This

image shows the spool lip that must have clearance with the magnet assembly. This

image shows the spool lip that must have clearance with the magnet assembly.

The

image right shows the inside of the

magnet cup ground which was required to move the entire assembly closer to

the center to make room for the inside of the spool lip. The

image right shows the inside of the

magnet cup ground which was required to move the entire assembly closer to

the center to make room for the inside of the spool lip.

The

image right shows the outside of the magnet cup assembly ground to complete

the clearance required for the inside lip on the spool. Also notice that I

had to grind a little off the top outside edge of the magnet in order to

complete the spool clearance. The

image right shows the outside of the magnet cup assembly ground to complete

the clearance required for the inside lip on the spool. Also notice that I

had to grind a little off the top outside edge of the magnet in order to

complete the spool clearance.

Here

are pictures of some different Magging options for a Avet Here

are pictures of some different Magging options for a Avet

SX, MX and LX/JX (have

the same construction.)

Magging my reel has

eliminated all backlashing. I can consistently get 60 - 70 yards with my 7

ft. rod. With a good 9-10 ft. rod and a small high quality reel you might

realistically expect to get 100 yds slinging iron.

Some thoughts on

backlashes: I use 30lb Spectra line with about 4-6ft. of Fluorocarbon

leader (15 to 40 lb.) this combo works great, I do not want any back

lashes. Back lashes and Spectra are mortal enemies. The no stretch quality

of spectra causes extreme weak spots in the line where the back lash snags

up the line and makes a birds nest. This snagging in the Spectra line

reduces the test by about half, I have even had the Spectra break when

backlashed. You do not want to get a backlash in your Spectra. If you do get

a good backlash you might want to cut that section of line out. A lot of

guys use up to a 100yd top shot of mono which eliminates this issue.

Magging your reel can

provide great benefits. Your reel will free line as before and give you the

confidence to power cast when necessary.

Try it you will like

it.

Walt

yessokk@msn.com

|